One sample part on display was a scaled-down version of an aerospace turbine casing (see the third image above) that illustrates the machine’s capability to build in two different materials. Uses for this machine include the manufacture of aerospace components, repair of damaged parts, and application of 3D coatings.

#Dmg laser machine software

DMG MORI provides specialized CAD/CAM software to support hybrid manufacturing, including independent postprocessors for subtractive and additive manufacturing. The width of the nozzle determines the minimum width of the path and wall thickness offering two options provides greater flexibility. The machine is now available with a 1.6- or 3-mm powder spray nozzle. Because the powder is blown into the laser beam (rather than held in a bed) no cleanup is required before such a change.

Dual hoppers enable switching the additive head between two different materials. Other improvements to the machining center’s additive manufacturing capabilities include:

#Dmg laser machine series

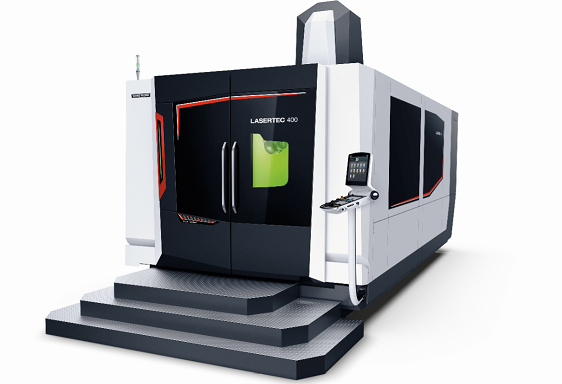

Video: Why the Failure? First Episode of Our New Series About Process Challenges in AM This capability makes it possible to run the machine unattended while maintaining required surface finish and porosity. But beyond simply recording this data, the system can also make adjustments to keep the build within specified tolerances. This information can be displayed on the control as shown in the second image above. The hybrid machine is now equipped with AMAnalyser, a system that tracks melt pool temperature and size, laser power, and argon levels, among other details, in real time. Foremost among these is the addition of melt pool monitoring technology, making the machine a closed-loop system. While the Lasertec 65 3D has been on the market for some time, DMG MORI emphasized several recent updates to the system during the event. A 2.5-kW diode laser melts the metal powder as it is dispensed, while argon gas provides a shield against oxidation. This machine tool is based on the company’s MonoBlock machining center design and uses a laser deposition process to build up parts additively, outside of a powder bed environment. One of the machines on display at DMG MORI’s Pfronten, Germany, open house this past January was its Lasertec 65 3D, a hybrid five-axis machining center that is equipped with a laser additive head.

0 kommentar(er)

0 kommentar(er)